Speed

The term "Speed" is defined in eTouch as the number of cycles per time quantity, depending on the machine settings in Balthzar Client. (Hereafter only referred to as "Client".)

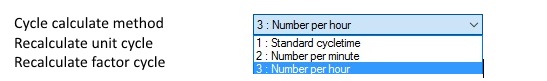

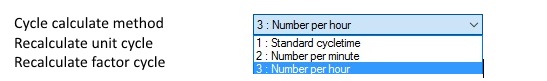

To change this, go to "Client" -> "Administration" -> "System settings" -> "Basic data" -> "Machines" -> "Machine parameters 1". Here is more information on how that form works.

Calculation of speed according to alternative 1 Standard cycle time

A machines calculated cycle time is calculated as planned cycletime * (cavities - cavity reduction)

Example:

Machine 100 is running an order which has a part which planned cycle time is 30 seconds. As soon as this machine produces less than 2 items per minute, the machine is running slower than expected, which is shown in eTouch in the following way:

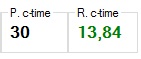

The opposite, when the machine is running faster than planned, is shown with a green number in the R.c-time field as shown below:

The formula used to calculate the real cycletime in the example above is:

Summed runtime since the order was started / number of cycles since the start of the order.

Calculations according to option 2, Number per minute means:

A machines calculated number (of produced units) per minute is calculated as (60 / planned cycle time in seconds) / number of cavities - cavity reduction.

In the example above, machine 100 is running with one cavity (and obviously no cavity reduction) and the part produced has 30 seconds planned cycle time. The planned speed using the calculation above is then (60/30) / (1-0) = 2.

Note the changed header texts compared to option 1.

The real speed is somewhat trickier to demonstrate since the amount of passed time always changes. The formula used however is

60 / (summed time since order was started / number of cycles during runtime)

In this particular example, the order had been running for 315 seconds and completed 10 cycles

According to the formula described earlier, the calculation would then be

60 / (315 / 10) = 1.904761904761905

Which is shown above as Real speed.

Calculation according to option 3 Number per hour

The speed calculated in option 3 is identical to the one used in option 2, except that the initial factor is 3600 instead of 60, resulting in the following calculation:

3600 / (315 / 10) = 114.2857142857143

(60 minutes * 60 seconds = 3600)< /FONT >

One thing to remember here is that the header texts of the boxes containing the numbers does not change. The user is supposed to know how speed is represented on the machine they are using.

Statistics order : Planned and real time per piece

In the statistics form of eTouch, historical orders are shown with yet another variation to speed, time per piece.

The reason for this being that theoretically, parts could have been produced in very different environments, i.e different machines, different operators and different settings. This new term makes all parts comparable ni regards to time spent per piece.

Obviously, a machine with more cavities is probably more effective in producing units than one with fewer cavities, however if the downtime of one machine is considerably longer than the other, the difference might not be as great as estimated.

Another thing to keep in mind is the quality of the produced units. If that is considerably lower in the machine with more cavities, it might even be more cost effective to only run production on the machine with less cavities.

To make an even stronger argument for the usage of real time per piece as opposed to speed in the sense discussed above, consider a machine with extremely high speed with large amounts of scrap compared to a machine with lower speed and high level of quality.

Which of the two is most efficient to run? In some production environments where the material can be reused, the cost of a scrapped item is relatively low, and in others its high, so there is no given correct answer. Aside from this factor, the time spent per good piece is probably the indicator you want to use, since planning and ability to deliver is depending on it.