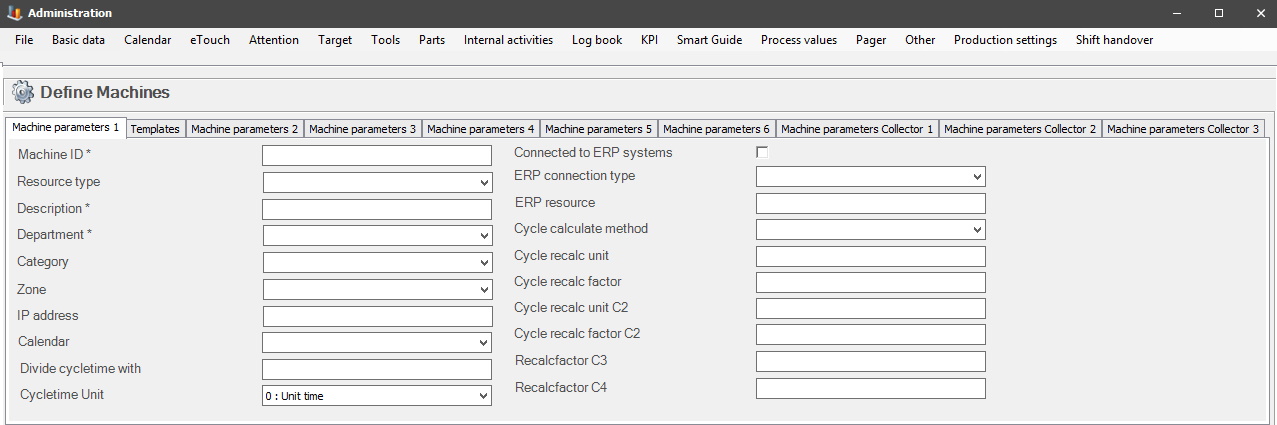

Here are the settings for "Machine parameters 1".

OBS! Be aware that during the start up process for new machines server programs such as Balthzar ERP, and ERP Connect must be restarted. This is needed to make sure that theese programs will take any / all new changes made into effect. The programs will read any / all changes made at restart, not automatically. If any additional help is needed, contact Delacroys support.

Machine ID

The machine ID can be a combination of numbers

and letters. Usually something that either describes what the machine does,

and/or corresponds to the ID of the machine in the ERP system if an ERP system is

used. However, there are a number of signs that can NOT

be used. They are the signs that are not allowed to

use when naming folders in Windows. See a list below:

\ / : * ? " < > | #

If any of the signs above are used, then the system will issue a warning that will explain that a sign that is not allowed has been used in the machine ID, and the user will have to try again.

The maximum numbers / letters that is currently allowed in a machine ID is six (6).

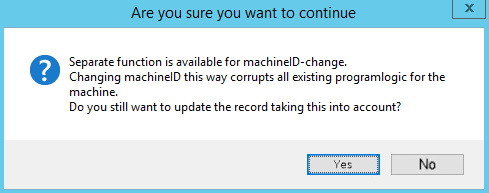

If you wish to change the ID of a machine there is a specific function that does this. Via " Client" -> "Administration" -> "System settings" -> "Other" -> "Change Machine ID" there is a form where you can change the ID of a specific machine. Here is more information on how that works.

If you still try to change the machine ID in this form, a warning will appear, seen below. This warning will inform the user about the correct way to change the ID of the machine.

To see a machine in the web application BZX21 it has to be added to a list for the web application. This is done in the settings for users. Go to "Client" -> "Administration" -> "System settings" -> "Users". In that section select the tab for "Web settings". In that form select a user, then activate the checkbox called "Web user". Once that is done select the machine/s from the "Show machines" list. Either one at the time, or all at once.

Resource type

In

this drop-down menu, it is possible to select a specific

resource type for the machine. See more information in the list

below.

0 - Direct time (standard value) - This is the normal choice for a machine, or a manual station used in the system. Time gathered here is considered by the system as direct time and will be able to be used for work orders.

1 - Indirect time - This resource type is only used to gather indirect time. It cannot be associated with a work order. An example of indirect time can be a department. If, for example, you wish to gather time for the tool department.

2 - Planning - This resource type is used to fine tune work orders in a section called "Detail planning" in the web application BZX21. When this resource type is used, then at least one of the available resources for the work order must be of this type. This is also used together with resources of the type "0 Direct time".

To activate this for the web application go to "Client" -> "Administration" -> "System settings" -> "Basic data" -> "Users" -> "Web settings". Once there activate the checkbox called "Resource planning".

9 - Other - This option will include

the remaining resource types. It can be used together with internal

activities. If, for example, a compressor has to be set up together

with scheduled internal activities, this is the type of resource you

use.

Description

Description of the machine, this is used in

various reports, and lists. This can be changed later if needed. If it is changed,

it will not affect any other logic in the system.

Department

Department this

machine belongs to. Department is, just like "Zone" and "Category", terms used

to group machines with similar properties such as placement, capacity, or some

other arbitrary, user-defined feature. To add new/edit existing ones go to

"Client" -> "Administration" -> "System settings" -> "Basic data"

-> "Department" "Category" "Zone".

Category

A term used to group machines, see

Department above.

Zone

A term used to group

machines, see Department above.

IP-address

The IP address of the databox used, and which

the system listens to for data traffic. (Usually, it's possible to surf to

the databox to do additional configuration if need be.)

Calendar

First select the machine for the calendar, second go to this

drop-down menu, and select the calendar. Here is more information about

how to create/edit calendars.

Site

The geographical placement of the machine is a term used

to group machines. Currently not in use, reserved for future use.

Divide cycle time with

The

factor used to divide cycle time with before presented in both Client, and

eTouch. This is always a numerical

value and it is used to adjust the data imported

from the ERP system.

Cycle time unit

The choice made here will determine the type of planned time the

ERP System will deliver for the production. Two choices are available:

0: Unit time

1: Cycle time

The exact definition of the terms is up to each customer to decide. As standard it refers to the production of a detail of some kind, for example, a unit, a kilo, a roll etc. The difference between the two choices lies in how the machine will measure speed in the production. If Unit time is selected, then it will measure the speed in the production per unit. If Cycle time is selected, then it will measure the speed in the production per cycle.

There are several settings that can affect the production for unit time/cycle time, for machine/s, tool/s, part/s etc. For example: If a machine runs a work order with a specific tool that has four inserts and is supposed to produce 1 cycle per second. Then it will produce 60 cycles per minute, 3600 cycles per hour, and then 3600 * 4, in total that is 14 400 details per hour when the tools inserts is included. If any scrap is done under the production, then that will also have an impact on the number of produced cycles.

Whatever the choice here is, it will affect what you

choose in the Cycle calculate method below. If for example, Unit time is selected,

then the first option of Standard cycle time should not be

used. If for example, Cycle time is selected, then the options of Quantity per

min/hour should not be used.

Connected to ERP systems

If this checkbox

is activated, then Balthzar will register its transactions in the

selected ERP system. It is recommended that any changes made here are made with

consultation to Delacroys

support.

ERP connection type

The list here will show which ERP systems that Balthzar currently

supports. Any/all choices made here are made by the developers at Delacroy in consultation with the

customer. If 0 = Standard is selected, it will collect data from the ERP Connect

program which has separate documentation.

0 = Data is synched from the ERP Connect

program.

1 = Data is read directly from the Monitor

ERP system.

2 = Data is read specifically according to

Hanzas requirements.

3 = Data is read directly from the Pyramid

ERP system.

4 = Data is read directly from the

Jeeves ERP system.

Example:

1001#3001#3501 this will show planned orders for manufacturing groups 1001,

3001, and 3501.

If this field is left empty, then the system

will

interpret that as if there are no manufacturing groups, and

will instead look for machine ID.

1. Standard cycle time

This will

calculate the time it will take for the machine to finish one cycle, and start

up another cycle, in

seconds.

2. Quantity per minute

This

will calculate the quantity of cycles produced on the machine during the last minute.

3. Quantity per hour.

This will

calculate the quantity of cycles produced on the machine during the last

hour.

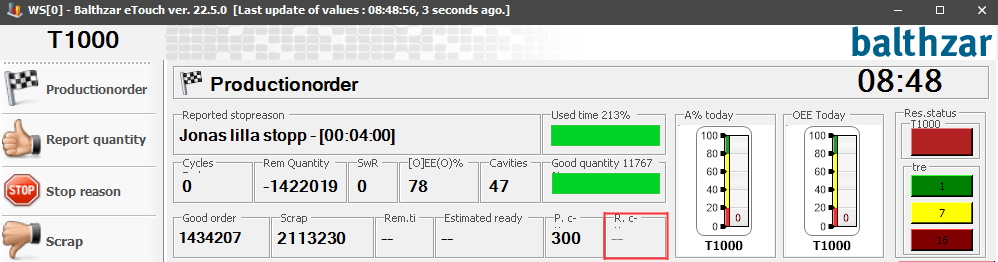

Please note that the choice here will also affect the data seen in the production order menu in eTouch. Specifically, the info seen below for "Real cycle time". If this field is left blank, then no data will be visible for "Real cycle time" in eTouch.

Cycle recalc unit

This is the unit used when

calculating cycles. For example, meters, pieces and so on. This is user

defined and can be added via "Client" -> "Administration" -> "System

settings" -> "Basic data" -> "Units"

which has separate documentation. Also known in the system as

cycle recalc unit 1.

Cycle

recalc factor

The factor with which the machine

box number will be multiplied before the system will

display it as "Number of cycles" in eTouch and/or the overview

of the Client. This is used if the machine production is in another

type of production, then units. For example, a machine used in a production scenario of paper

production could send x number of pulses per meter paper instead of units. If that

is the case, then cycle recalc factor is used. Also known in the

system as cycle recalc factor 1.

Cycle recalc factor C2/C3/C4

Same as above

with cycle recalc factor, this is used if the machine box sends more

than one

signal

to the system.