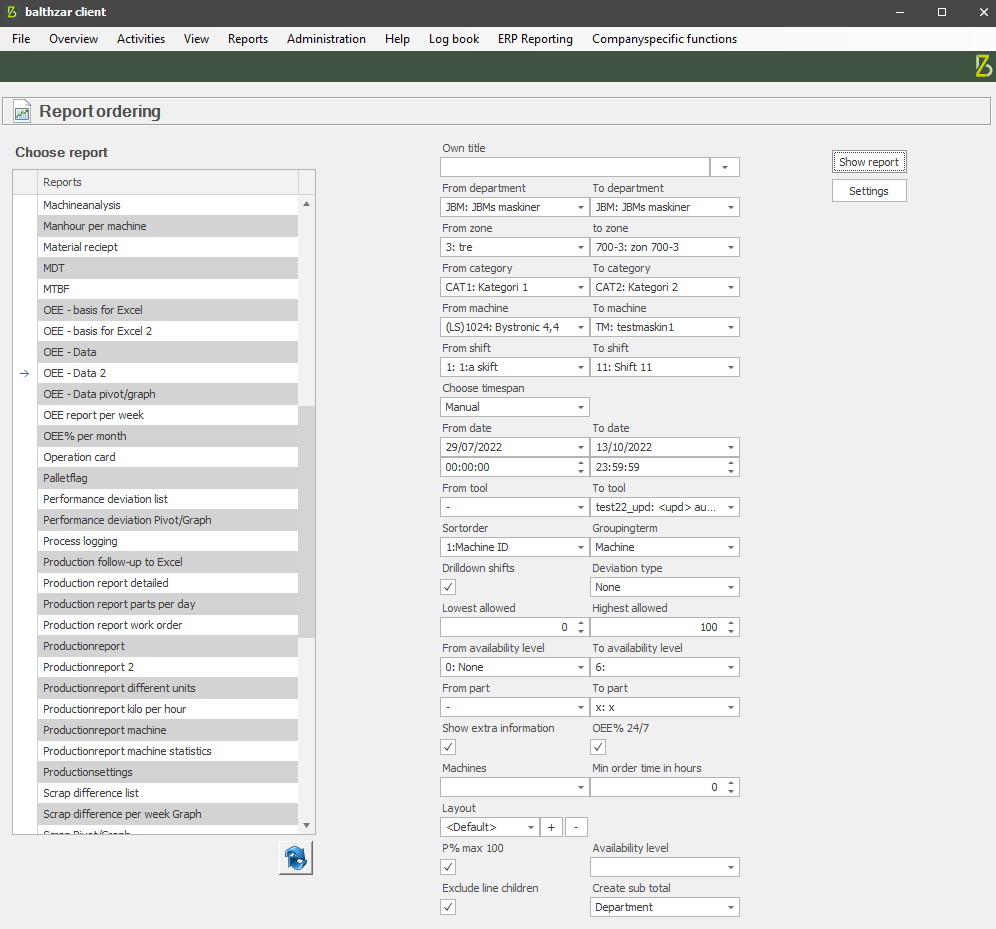

The idea behind this report, OEE - Data 2, is the same as the previous report OEE - Data, which was to show OEE related date based on essential terms. The Report OEE - Data 2 is a follow up to the original OEE - Data report and therefore you will see that it has many common attributes and settings.

Please note that all future development will be focused on OEE - Data 2 report.

In this report you have a number of different groupingterms to choose from. You can see more information about each option below.

Department

Zone

Category

Machine

Shift

Timespan

Tool

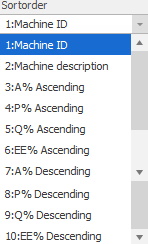

Sortorder

Here you

can select an option for which the report will be sorted

on. Currently you can choose one of the following options. Machine ID,

Machine description, A% Ascending, P% Ascending, Q% Ascending, OEE% Ascending,

A% Descending, P% Descending, Q% Descending, OEE% Descending. See the picture

below.

Grouping term

Here you can choose between different options which

will determine what grouping term the report should be based on. For

example

Drilldown

shifts

If you tick this box the report will be divided per

shift, each machine will get one row per shift. Machine ID, Tool

ID, Part ID etc.

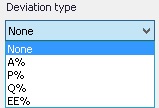

Deviation type

A set of

terms that can further limit the values of

the report related to the values of O%, E%, E%, or OEE%.

Lowest/Highest allowed

The timespan in which the choosen deviation type

should be within.

From/To

availability level

The specific interval of availability levels

which should be a part of the report. To edit levels go to "Client" ->

"Administration" -> "System settings" -> "Basic data" -> "Stop reason"

-> "Stop reason 2" -> "Availability level". Here

there

is more information about how it works.

Part

number From/To

The specific parts which should be included in the

report.

Show extra

information

If you tick this box four more

columns will be added to the report and they are: "Turn-out quantity", "Target

quantity", "Diff quantity" and "Diff

time".

OEE%

24/7

This tickbox will change how the report will calculate the OEE% value. With this

activated it will calculate the OEE% value as O0%*E%*E%, instead of the

standard version which is O%*E%*E%

Machines

A drop down menu where you can select what

machines you want to be included in the report. Please note that if these

machines are somehow excluded in any of the other selections they will not be

selected here no matter if you choose them or not.

The difference

between the options "Select All", and "All" is that "Select all" will only include

all machines that exists when the choice is done. If any new/future machines should

be included automatically the option "All" has to be selected.

Min order time in hours

This is the

time which the current running order has been up and

running. If this selection is part from 0 we will only take data for the orders which are currently

up and running as well as the orders which have been running for x hours.

You can set the value manually or use the arrows to reach the desired

value.

Layout

Here you can choose to either use the

standard layout or go for your own version. You can reach the design guide if

you click the plus sign. You can also choose between available designs in the

drop down menu. There is more information about the report design guide here.

P%

max 100

If

this tickbox is selected the calculation of P% is corrected so

that even if the actual value of P% is above 100 the system will

correct it to 100. This is true regardless of which choice

of groupingterm is selected. For example, if Departments are

selected as grouping term then the departments P can't go over 100%,

or if you choose to group on machines the selected machines P can't go over

100%.

Availability levels

In this drop-down menu you can select different

availability levels for this report. This can be edited via "Client" ->

"Administration" -> "System settings" -> "Basic data" -> "Stop reason"

-> "Stop reason 2" -> "Availability level". Here

there is more information about how that form works. For

this to work as intended the selected levels has to be within from the

value as well as to the value, AND within the selection.

You can choose if you only wish to display these values or "OEE" values which are greater than or smaller than a certain value. To set this up you can choose a "deviation type" and enter values in the "lowest allowed" and "highest allowed" menus. Please note that as standard the system will choose the option "None" here. This means that the user have to make an active choice here in order to see any related information when viewing the report. The letters stand for:

A%

Availability in % is calculated run

time / (run time + stop time).

P%

Performance in % is calculated

earned hours / (earned hours + scrap prod time / run time).

Q%

Quality in % is calculated earned

hours / (earned hours + scrap prod time).

OEE%

This term stands for Overall Equipment Efficiency and is a summary of previous

parts and will show you an overview of the selected machine. Is calculated A*P*Q

(Availability * Performance * Quality).

Exclude line

children

If this checkbox is activated, then only the

machines designated line parents will be visible in the report viewer. Machines designed line

children will be excluded.

To set up new/edit old machine lines go to "Client" -> "Administration" -> "System settings" -> "Basic data" -> "Line". Here there is more information on how that works.

However, machines that are not included in machine lines will be visibile in the report viewer regardless of this checkbox status.

Create sub

total

Here the selection will be based on

which overview that is selected. There are four options

here: None/Category/Department/Zone. For example, if Department is selected, it will have its own section in the report viewer called Department.

To create

new/edit existing overviews go to "Client" -> "Main menu" ->

"Overview". Here there is more information

on how this works.

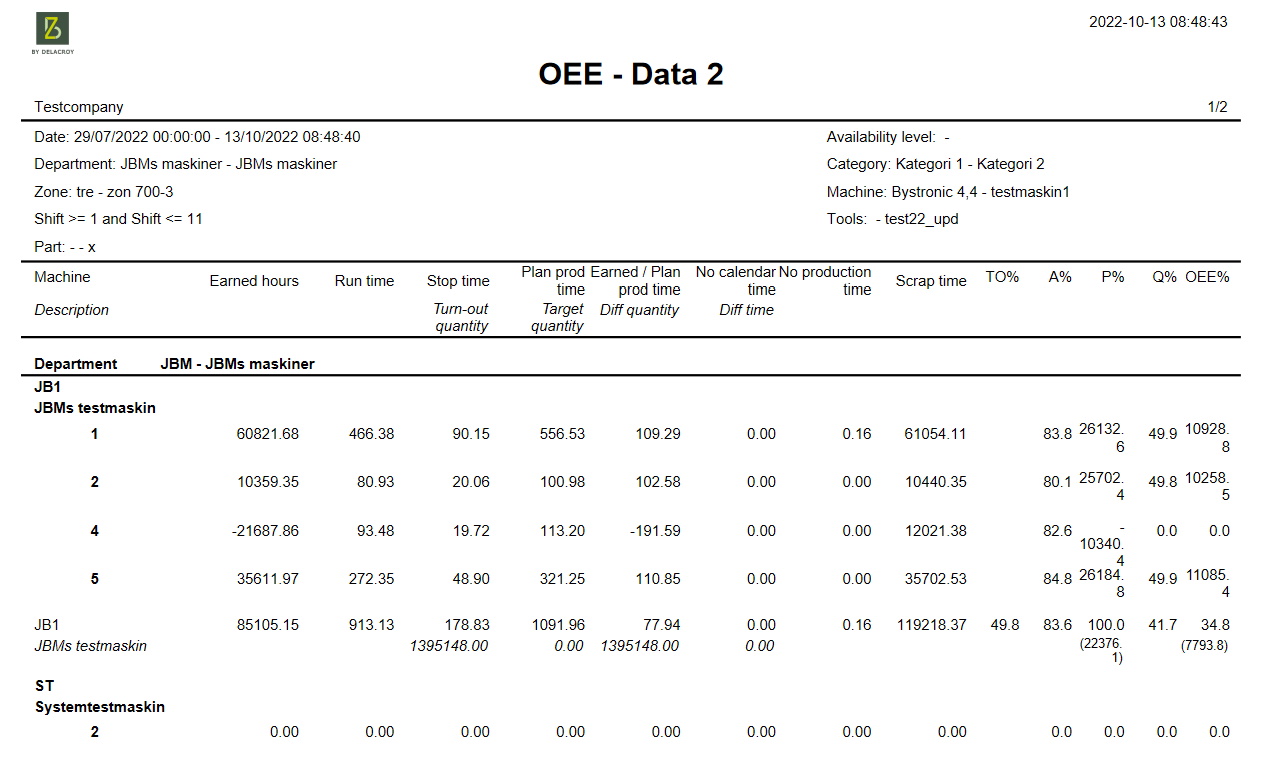

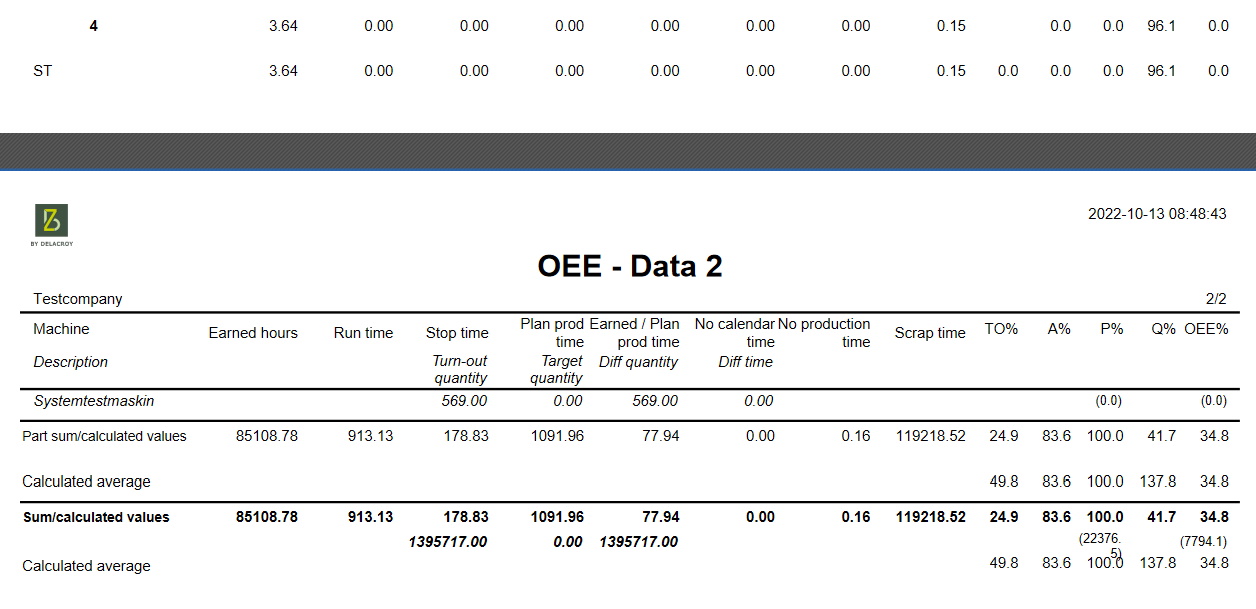

Below you can see what the selection in Client looks like, as well as an example of how the report will look like in the report viewer. Please note that the checkbox called "Show extra information" is active.

It is important to note that after each machine's data is shown there is also a row for a summary for each machine and this will not be included in the final summary. Below you will find an explanation for the columns shown in the report.

Earned

hours

Is calculated as Approved produced quantity * planned set up

time.

Run

time

Here you will see data for the machines

run time.

P% loss

stop

If the stop reason has the flag "Speed loss" assigned to

it it will be listed here. This stop time will NOT appear in the column for stop

time. These stops will not affect the availability (A%) but will

instead affect productivity (P%).

Stop

time

The machine has been still during calendar time, stop

reasons which are not "production time" are excluded.

Turn out quantity

How many

products the machine has produced. This will be calculated as: cycles *

(reductions - cavity reductions) * realcalculationsfactor.

The following SQL

query will be made:

CASE dbo.object_machines order_qty_calc

WHEN 3 THEN 0

ELSE ISNULL

(dbo.object_transaction.cycles.0)*(ISNull(dbo.object_work_order.insatser.1)-

ISNULL(dbo.object_work_order.cavity_reduction,0))*

ISNULL(dbo.object_machines.cycle_recalc_factor,1 )END AS

produced_qty

Plan prod

time

The time which the machine is planned to be running an order.

Is calculated as run time + stop time.

Target quantity

How many

products the machine should have produced if it had run as planned. This

will be calculated as: (runtime + stoptime) * timedistribution * capacityfactor

* planned cycle time.

The following SQL query will be made:

CASE

object_machines.cycle_time_unit WHEN 0 THEN

CASE

isnull(dbo.object_stop_reasons.production_time,N'yes) when N'yes' then

case isnull(dbo.object_transaction.shift, 0) when 0 then 0

else

case isnull(dbo.object_work_order.plan_cycle_time,

1) when 0 then 0

else (dbo.object_transaction.run_time +

dbo.object_transaction_stop_time) *

CAST(ISNULL(dbo.object_work_order.time_share, 1) AS float) *

ISNULL(dbo.object_work_order.capacity_factor,0) /

ISNULL(dbo.object_work_order.plan_cycle_time, 1) end

end

else 0 end

ELSE 0 END AS target_qty

Earned / Plan prod

time

This is calculated as Earned hours / plan prod time.

Diff quantity

Shows how much time that is earned/lost depending on the diff

quantity if the machine had run at the target speed.

At the last column in the report, a sum is shown. However, in the case of OEE%, this is not a sum of the values above, rather a calculated sum based on all values the report takes into account for the A%, P% and Q% terms.

No calendar

time

No calendar time is time for when the machine has been active

outside the designated calendar time.

Diff time

Here you will see the difference in time between diff quantity and

diff target. If the machine was running at target speed.

No production

time

No production time is time for when the machine has been

stopped with a stop reason which has "no production time".

Scrap production

time

Scrap production time is calculated as scrapped quantity *

planned time per piece.

TO%

Here you will see data for availability

based on all the time for the selected interval. Please note that there

is no consideration taken regarding calendars or any other related information.

A%

Here

you will see data for availability (A%) and this is calculated as runtime /

(runtime + stop time).

P%

Here

you will see data for productivity (P%) and this is calculated as (earned hours

+ srap prod time) + runtime + P% loss stop).

Q%

Here

you will see data for quality (Q%) and this is calculated as (100 - (scrap

quantity / (Prime quantity + scrap quantity) *100).

OEE%

This

term stands for Overall Equipment Efficiency and is a summary of previous

parts and will show you an overview of the selected machine. Is calculated A*P*Q

(Availability * Performance * Quality).