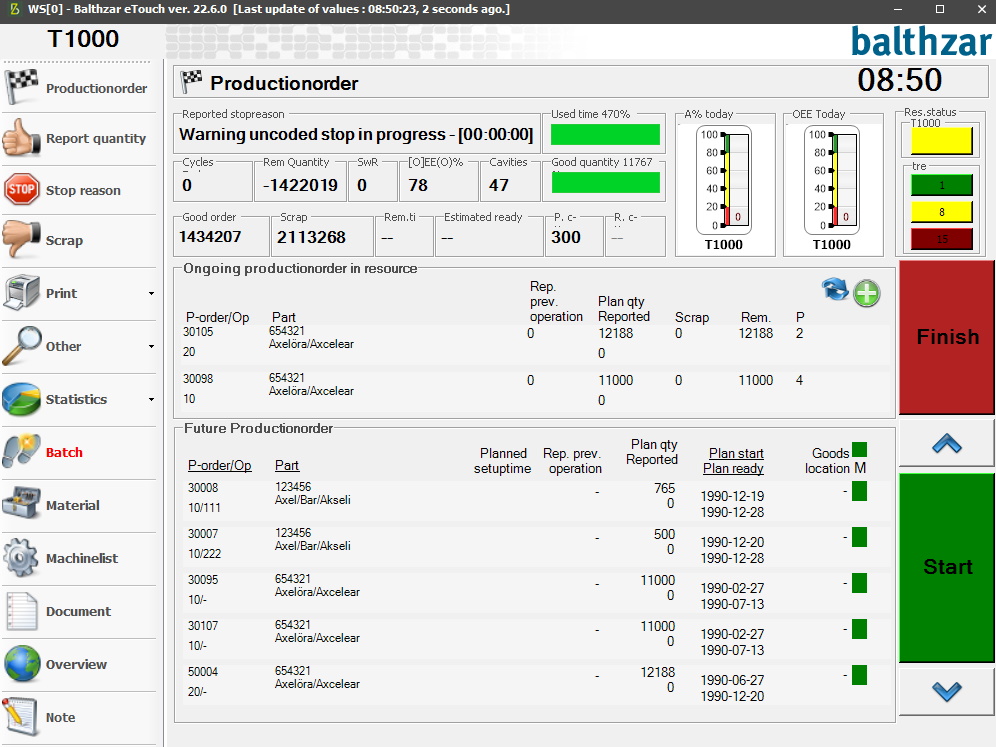

Explanations for what is shown in the picture

above

Via "Client" ->

"Administration" -> "System settings" -> "eTouch" -> "Define eTouch

parameters" -> "eTouch parameters 1" -> "Time interval(s)"

it is possible to change how often values are updated. This

will only affect the values in the upper section of this form, from

Reported Stop reason to OEE Today.

For example, if the number ten, 10, is entered here. Then the values from Reported Stop reason to OEE Today will be updated every ten, 10, seconds.

Reported stop

reason

The

stop reason is in effect at the moment, if the machine isn't running and a

reason for this has been supplied.

Cycles today

Number of

registered cycles today.

Rem Quantity

The

remaining quantity of this order before the planned quantity is reached.

SwR

The number of uncoded

stops. If this number is greater than zero (0) you can press the number to get

to a form where uncoded stops can be coded for the ongoing shift.

[O]EE(O)%

Here you will see data regarding [O] in OEE which

stands for "Overall Equipment Efficiency". However, there is no direct translation available

here so the English version will be calculated as A=

Availability, P=

Performance, and Q =

Quality. OEE% is a

summary of the previous parts and will

show

you

an overview of the production of the

selected machine.

Cavities

The number of cavities used. The term "cavities" will the system

interpret as "the number of details produced per cycle per machine". What

this means in practical terms depends on different circumstances. It might be a

part of a tool, an entire tool, or part of a tool that produces several units per cycle.

Good order

This is the produced quantity considered

to be of approved quality.

Scrap

Scrapped quantity in this order so

far.

Rem. time

Estimated remaining time until

this order is finished. Calculated based on current speed, and remaining

quantity.

Estimated ready

Estimated date and time when

this order will be finished. Calculated based on current speed,

remaining quantity, and active calendar.

P. c (Planned cycle time)

Planned cycle time is the average production time that is needed to be able to finish the production order in time. This will require that you have full production on the active machine during the ongoing production orders scheduled dates.

For various reasons the production might miss the scheduled date if, for example, there is a lack of material for the production, or the machine is undergoing service. It is possible to catch up with any lost production time if you increase the production speed or maintain production outside the scheduled production time.

R. c (Real cycle time)

Real cycle time is the actual speed for the production that the machine has right now. However, this can be changed depending on which method you use to calculate cycles. Changed this via "Client" -> "Administration" -> "System settings" -> "Basic data" -> "Machines" -> "Machine Parameters 1" -> "Cycle calculate method". Here there is more information on how this works.

Used time %

Percentual representation of used time, This means the amount of time related to the amount of planned time. In reality the amount of time the machine is running with a work order active, during the scheduled calendar for the production time for the machine.

Good quantity %

Percentual representation of produced quantity,

A% Today

Shows data for A% today which is short for Availability and is calculated as (run time - stop time) / run time. This refers to the amount of time that is the actual production time for the selected machine. The remaining time is made up of various stop reasons.

OEE Today

Shows data for OEE today, and OEE is short for Overall Equipment Efficiency. This is calculated as A*P*Q which stands for Availability, Production, and Quality. Here you can read more about how OEE works.

Res. status

Shows the status of this production resource in three different colors. Green means that the machine is running, yellow means that the machine is standing still with a reported stop reason, and red means that the machine is standing still without a reported stop reason.

Tre

Here you can find the name of the currently

selected department/zone/category the selected machine is located in. This is

controlled via "Client" -> "Administration" -> "System settings" ->

"eTouch" -> "Define eTouch parameters" -> "Parameters 1". In there you

have to go to the menu option called "Group by", and there you will find the

selections mentioned above. Here

there is more information

about how that works.

Ongoing production order in resource

Here you can see data related to the ongoing production orders.

P-order/Op

The ID of this production order, if available, will also show the ID of the operation within this production order.

Part

The ID of the part, and the description of the part currently produced.

Rep. prev. operation

Reported quantity in the previous operation.

Plan. qty. reported

Planned quantity of this production order.

Scrap

Here you will see the quantity of scrap for this production order, reported to the ERP system.

P

Position this order is used at.

Refresh arrows

If you have a direct connection to the ERP system Monitor you can use these arrows to refresh the data shown in the production order menu. If you don't have a direct connection to Monitor and click on these arrows nothing will happen.

The plus sign

The green and white plus sign next to the

arrows indicate that there are additional ongoing work orders. When you click on it a

new form will appear where you can manage this. Here

there is

more information about how that works.

Future production order

If there are any upcoming production orders for this machine, you can see them in this list.

P-order/Op

The ID of this production order, if available, it will also show the ID of the operation within this production order.

Part

The ID of the part, and the description of the part if available.

Rep. prev. operation

Reported quantity for this upcoming production order.

Plan qty reported

Planned quantity for this upcoming production order.

Plan start/Plan ready

Estimated dates for when the upcoming production order is supposed to be started and finished.

Goods location

Here you will see where the material for the upcoming production order is stored.

M

What the letter M stands for is

"Material Control". This checkbox can be activated via "Client" ->

"Administration" -> "System settings" -> "eTouch" -> "Define eTouch

parameters" -> "eTouch parameters 2" -> "Material Control". Here there is more

information on how that form

works.

Once that is activated it will use different

colors to indicate the status of the reported quantity. If the

previous operation reported quantity is <= 0 a red

box is visible. If the previous operations reported quantity is less

than the current operation but larger then 0, than a yellow box is visible. If

the previous operation reported quantity is larger than, or equal

to the current operation than a green box is

visible.

The different colors in this box will indicate if an operator is expected to be able to complete the current operation without running into a loss of materials. If the color red is used = No the operator will not be able to finish the operation at all due to a material loss. If the color yellow is used = The operator will be able to finish the operation, but it will still indicate a material loss. If the color green is used= The operator will be able to finish the operation as planned without any material loss.

Buttons

As stated before the production order menu might look different depending on whether you have special functions activated or not. As standard, there is only a start, and a finish button available. You have to select a production order in either future- or ongoing production order to use these buttons. The arrows between these buttons are used to scroll up and down in the list of available production orders.

Production order, general information

Balthzar is using quite a few scheduled functions to update the values shown in this picture. Most of these scheduled functions are run at specific intervals which can be configured by the system administrator. Depending on what functions are used this will affect the performance of the database server differently.

It is also important to know that it is possible to prioritize in which order each function should be updated. For example, it might be considered important to have more frequent updates of prima quantity on production orders. This setting is changed via "Client" -> "Administration" -> "System settings" -> "eTouch" -> "Define parameters in eTouch" -> "eTouch Parameters 1" -> "Status interval". This section has separate documentation here that will explain how this works.

A lower number will mean more frequent updates, but this will also affect the performance of the system. This is important to keep in mind when you take into consideration the number of affected machines and their hardware. If for example number 5 is used it will update more often, but that will hurt the performance of the system. This should only be changed by the system administrator. if any additional information/help is needed, Delacroys support should be contacted.