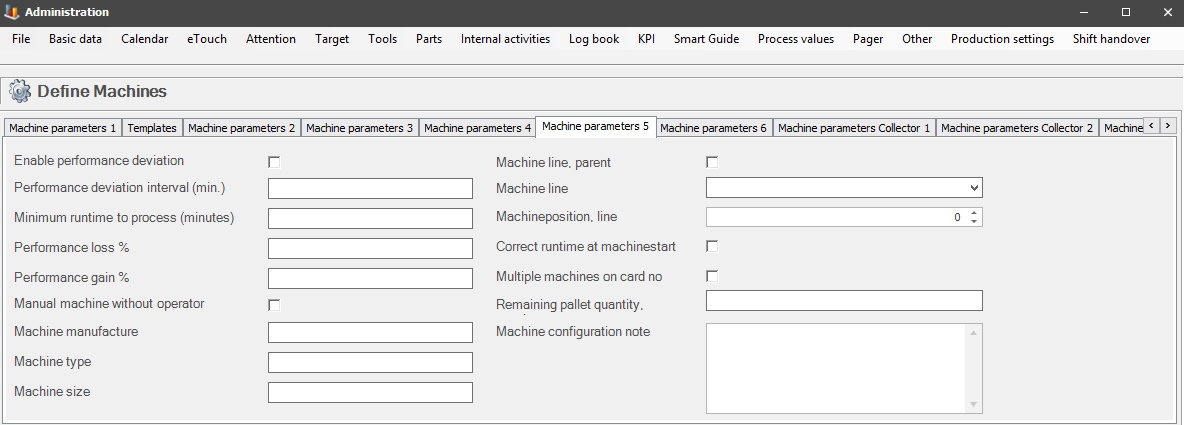

Here are the settings for "Machine parameters 5".

Enable performance

deviation

Tick this box if you want to enable performance

deviation. Set this up

via "Client" -> "Administration" -> "System settings" -> "Basic data" -> "Performance

deviation".

Performance

deviation interval (min.)

If

performance deviation is activated this will determine how much/if any

deviation this has. This will determine the amount of data available during

the presentation of performance deviations.

Minimum run time to

process (min.)

Here you enter the minimum run time, which will include both run time and stop

time.

Performance loss

%

Here you enter the limit in % that are acceptable as

a performance loss during production. If 100 pcs are produced, and the

goal is to reach an approval rating of 90%, then the performance loss is 10%.

Performance gain

%

Same as above, but for performance gain instead.

Manual machine

without operator

if this checkbox is activated it is not required to manually login at this

machine.

Machine

manufacturer

Here you will enter information about the manufacturer of the

machine.

Machine

type

Here you will enter information about what type the machine

is.

Machine

size

Here you will enter information about what size the machine

is.

Machine line

parent

This checkbox is only used if the selected machine is part

of a machine line. If it is activated the selected machine will get the status

"Parent", and the other machines in the machine line will have the

status "Children".

To set up a machine

line go to "Client" -> "Administration" -> "System settings" -> "Basic data"

-> "Line".

Machine

line

Here it possible to select a machine line. Each

machine that the machine line consits of has to be added manually to the machine

line.

Machine position

This is only used if the machine line has more

than one machine. If it does, use this to determine which position each

machine has. This is used to separate the machines in reports, and/or the web

application BZX21.

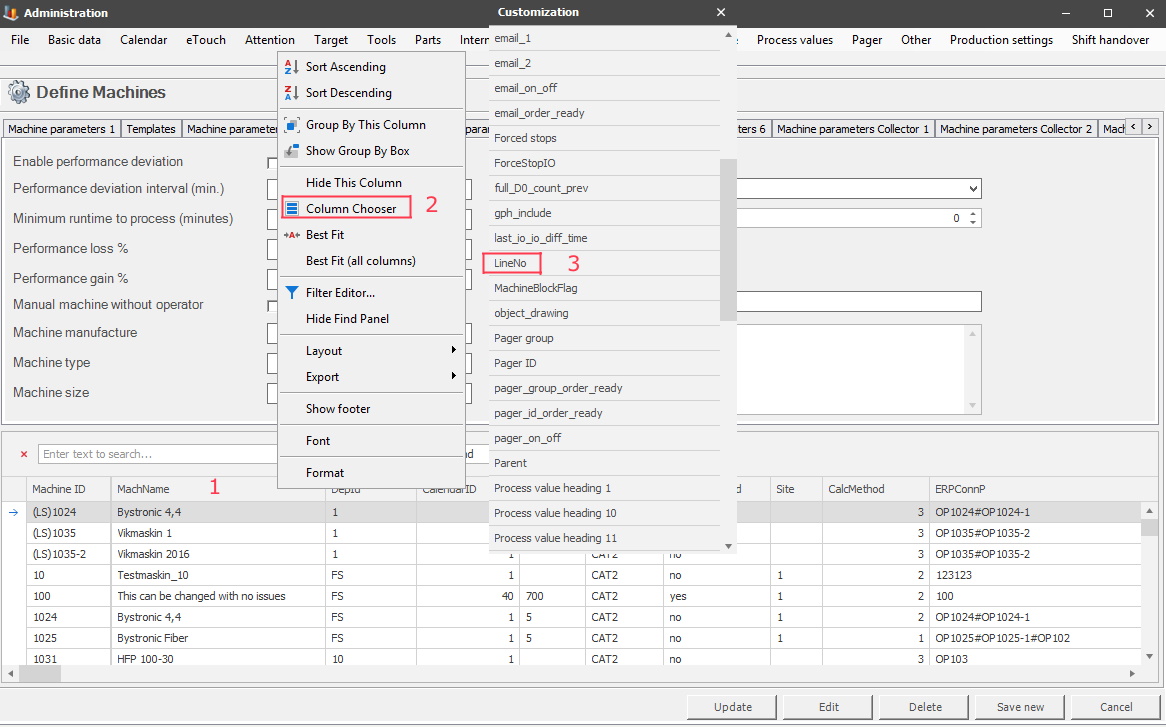

When a machine line is created there are different ways to see which machines that are included in that line. One option is to create a specific filter for it. Here is more information on how filter works.

Another option is to add "LineNo" to the columns seen in the filter in the picture below. Right-click on a column header, see 1, to open up the menu where "Column chooser" is located. Then select it, see 2, and in that new menu drag and drop the option called "LineNo", see 3, to the table of columns. Once added remember to right-click on a column header again, then select the option "Layout", then "Save Layout" to save the changes made. The changes will now be saved next time a log in/out occurs.

Correct run time at machine

start

If this checkbox is activated, the machine

will automatically correct its run time to compensate for any erroneous planned cycle time. This is to

make sure that the planned cycle time is reasonable.

Multiple machines on card

no

Card no is a term used in the system to

describe the production order. With this checkbox activated there can be

multiple machines on the same production order.

Remaining pallet quantity, warning

This field is connected to a special

function called 323 Show pallet in

eTouch which has separate documentation. The number entered here

will act as a limit in eTouch, and when it is reached a warning will be

visible that will show that the production of pallets is soon

complete.

Machine

configuration note

If you want to enter additional information about the

machine's configuration you can do this here.