This will be a step-by-step guide on how to add parts in Balthzar. Contact Delacroys suppor t if any additional help/information is needed.

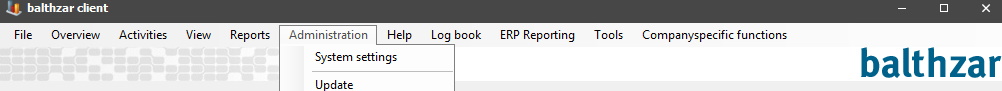

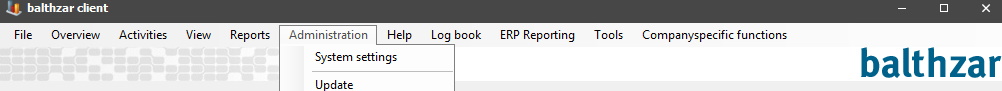

1. Via "Client" -> "Administration" -> "System settings" -> "Parts" -> "Enter parts" you will find the form where you enter information about existing/new parts in Balthzar. Here there is more information about how that form works.

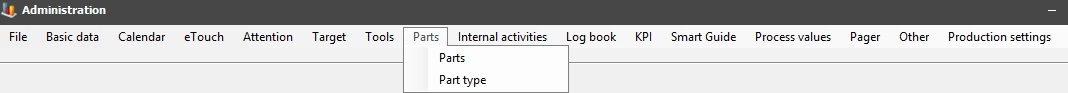

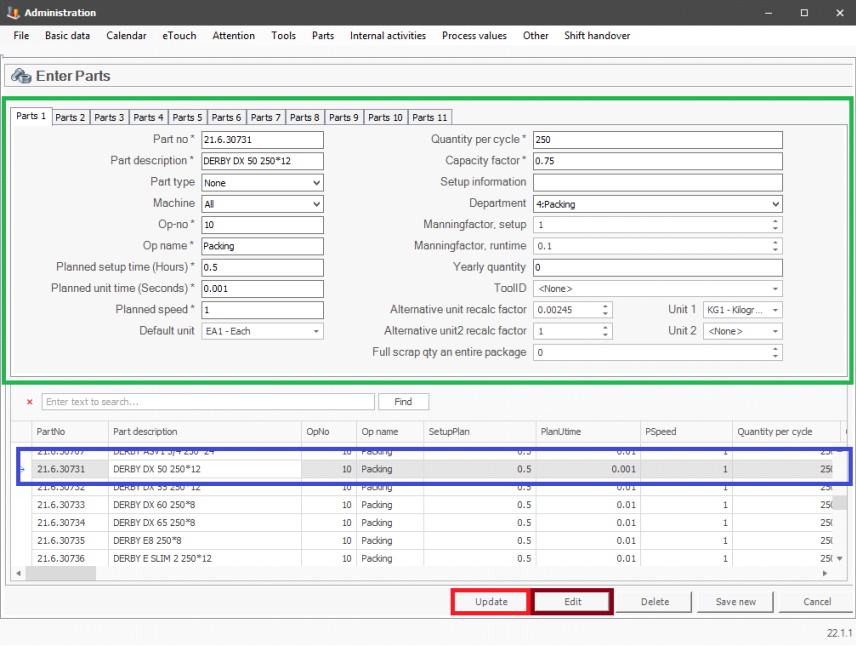

2. The form visible below will match the form in the Parts section of Balthzar. The green box is where you enter information when you create a new part. The red box lists shortcuts to the other forms in the Parts section of Balthzar. The purple box will list existing parts. Finally, the blue box shows the search box, here you can enter the ID of the part and search for it.

3. Picture number three will show an example of how it might look like if you edit an existing part. In the blue box, the selected part is highlighted. In the green box, the data for the selected part is visible. The brown box shows the edit button, and the red box the update button.

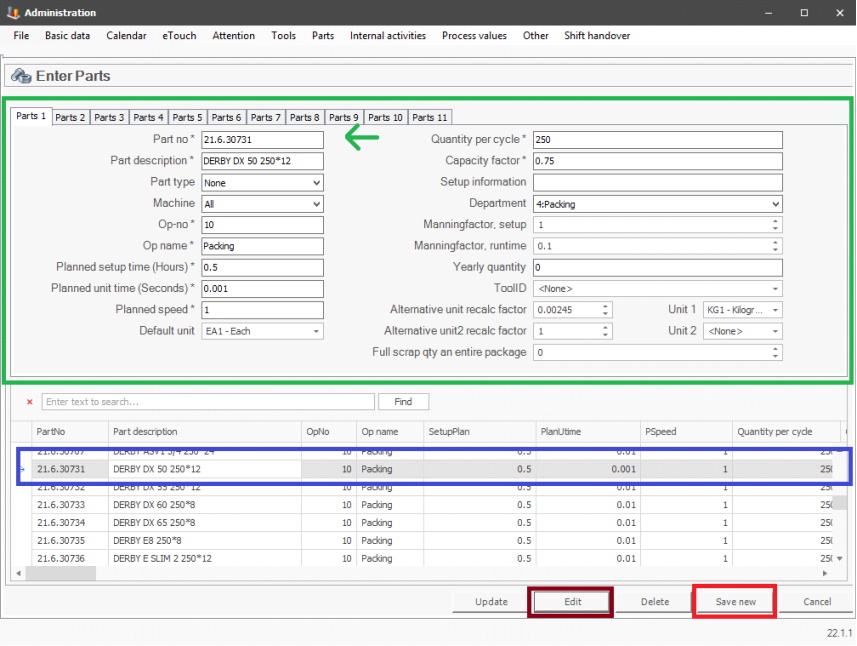

4. Picture number four will show an example of how it might look like when you have created a brand new part. The green box will show data for the new part. To save the new part use the save new button, the red box. Once saved it will be listed in the blue box. If you wish to edit it, click the edit button, the brown box.

Field explanation for pictures 2-4.

Tab parts 1

Part

no

Part

description

A description of what the part is, ex. DERBY ASV 1 3/¤ 250*24.

Part

type

What kind of type is the part, part type is set up via

"Client" -> "Administration" -> "System settings" -> "Parts" ->

"Part type". Here there is more information about

how that works. If no part type exists None will be selected. Ex.

Nails

Machine

If

the part is intended to always run on a specific machine it is selected here. If

it should be available on all machines there is an all selection available.

Op

no

The

operation number for the processing of the part.

Op

name

The

name of the operation for the processing of the part.

Planned

setup time (hours)

Here you set how long time in hours it should take to prepare the

machine before the production can be started.

Planned

unit time (seconds)

Here you set how long it should take to create 1 part when

the machine is running.

Planned

speed

Not used, always set to 1.

Default

unit

In what unit is the production measured, ex. each, meter,

kilo. This is set up via "Client" -> "Administration" -> "System settings"

-> "Basic data" -> "Units". Here

there is more information about how that form works.

Quantity

per cycle

This will determine how many parts are created during a cycle on the selected machine. Also known as

cavities in the system.

Capacity

factor

The capacity factor specifies at which capacity the part can be

expected to be produced.

If the machine at full speed

produces 1 unit per second, it can produce 3600 units per hour. With a capacity

factor of 1 (100%) we then expect the machine to produce 3600 units at all

hours. If the capacity factor instead is 0.5 (50%) we expect it to produce 3600 * 0.5 =

1800.

Capacity factor is specified in decimals, so 100% =

1 and 85% is 0.85.

Setup

information

Here you can add information that could be useful for the machine

operator to know during setup.

Department

With this setting, you can limit which machines the part can be

planned and started on. If this is set to department 1 and the machine setting

is set to all, all machines in department 1 will be able to start this part, but

no machines in the other departments.

Man

factor, setup

How many persons are needed to set up the machine when this part is

started.

Man

factor, Runtime

The number of persons needed to run a machine or machines. This can

be addressed in decimals since one person can run more than one machine. For

example, if one person runs two machines, you will use 0,5 as a value

here.

Yearly

quantity

If the part has any yearly goals, you enter it here.

Tool

ID

If

the part should be connected to a tool you select it here. Tools can be set up

under tools -> tools.

Alternative unit recalc factor

If we want to know how much we have produced in more than one unit, for example how many nails we have made and how many

kilos of nail that represents, we need to set this up here.

In our example, the default unit

is quantity, and 1 part weighs 0.001 kilos, the recalc factor is 0.001. (0.001 /

1)

If the default unit instead is in kilo, and one part still weighs 0.001

kilo, the recalc factor to calculate quantity becomes 1000 (1 / 0.001)

Alternative unit recalc factor, unit1

Here you set the name of the unit

calculated with alternative unit recalc factor.

Alternative unit recalc factor 2

If we want to know how much we have produced in more than

two units this is set up here. In our example how many nails we have made, how

many kilos of the nail that represents, and how many meters

of the nail that represents.

When we calculate the recalc factor for this we convert from

alternative unit 1 to alternative unit 2.

If the alternative unit 1 is kilos and alternative unit 2 is meter, and 1

kilo represents 50 meters of nails, the recalc factor 2 is

0.02. (1 / 50).

If the default alternative unit1 instead is in meter, and

one kilo still represent 50 meters of nails, the recalc factor 2 is 50 (1 / 50).

Note that calculating alternative unit 2 from the standard units

then is (standard quantity) * (alternative unit recalc factor) * (alternative

unit recalc factor 2).

Alternative unit recalc factor, unit2

Here you set the name of the unit calculated

with an alternative unit recalc factor 2.

Full

scrap qty an entire package

This is used when

calculating % of scrap qty of an entire package. For example in the special function 5, start order by

part, or the special function 341, report scrap through

packages,

which both have

separate documentation.