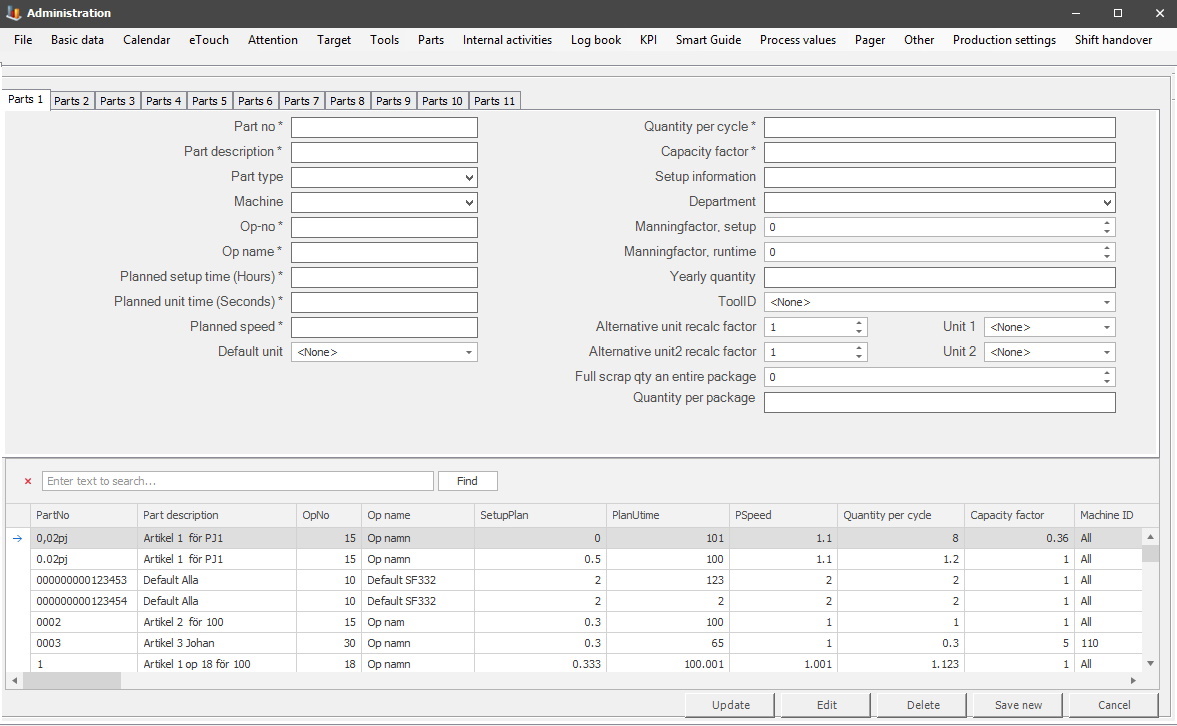

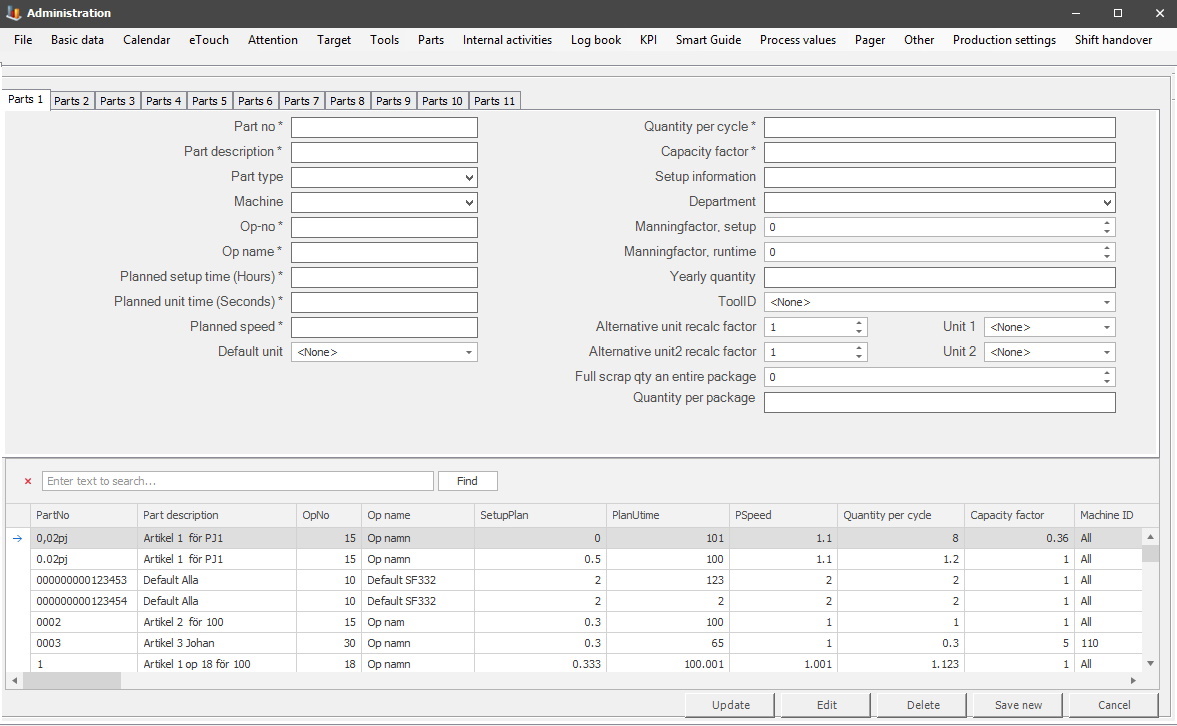

In this section you can create parts that will be used when starting work orders in the Client, the web application BZX21, and eTouch. For example, it can be used by special functions in eTouch, and the web application BZX21, or in the production section of the Client. There is also a guide that shows how to add/create parts in Balthzar.

Part no

The articles number, often the same as the number used in the ERP system.

Part description

A

description of the article.

Part Type

Here it is possible to assign a specific type

of parts. For example, if the part is supposed to be used with a specific type

of machine, create a part type for these machines, and select it here.

The form for this can be found via

"Client" -> "Administration" -> "System settings"

-> "Parts" -> "Part type":

Machine

Here it is possible to select a specific machine that the

part should be connected to.

Op

no

The operations number

for the processing process is described in the other fields.

Op

name

A description of the operation, it will be shown in eTouch for both planned and

active orders.

Planned setup time

The time, which

according to the schedule, should be used to set up the machine during or

before it is active. Specified in hours.

Planned speed

Planned speed

for the specific article, specified in seconds. Remember to pay attention

to inserts in specified tools when this value is calculated.

Default unit

Here it is

possible to see different types of units. It is up to each customer to define

which types, and what they mean. To add new types/edit old ones, go to "Client"

-> "Administration" -> "System settings" -> "Basic data" ->

"Units". Here

is more information on how this form

works.

Quantity per cycle

The number of articles after each completed cycle. In other parts of this

system, this is also called inserts.

Capacity

factor

Capacity factor is

specified in decimals, so 100% is 1 and 85% is 0.85. If you have a capacity

factor of 0 specified for an article, you want the capacity factor to be collected

from the machine. If the machine has "0" as a capacity factor, your

orders will automatically be assigned a value of "1" on started orders. But, if

you choose to not use a value at all, "", as a capacity factor this means that

you want to have a capacity factor

of 1 on started orders, without collecting any capacity factors from the machine or machines.

Setup information

If there is any specific information for this part that

needs to be addressed during the setup phase, then enter it here.

Department

Here it is possible to assign a

specific department for the part. This can be used as an additional search

criteria by the system. Go to "Client" -> "Administration" -> "System

settings" -> "Basic data" -> "Departments" to add new and/or edit

existing departments.

Manningfactor, setup

This is the

number of people needed to set up a machine or machines. This can be addressed

in decimals since one person can set up more than one machine for example

if one person sets up two machines you will use 0,5 as a value here.

Manningfactor, runtime

The

number of people needed to run a machine or machines. This can be addressed in

decimals since one person can run more than one machine. For example, if one person

runs two machines, you will use 0,5 as a value here.

Yearly quantity

This

field is optional to

use. It is intended to be informational

about the production goal of the year on this specific part.

Tool ID

In this drop-down

menu, it is possible to select a specific Tool ID that should be connected to

this part. To crew new tools, and/or edit

existing tools,

go to

"Client" -> "Administration" -> "System settings" -> "Tools".

Alternative unit recalc

factor

Here you calculate the produced quantity in an alternative

unit. You can apply this functionality in eTouch, when you start parts or in

the Client when you start parts.

Please note that it is up to each customer to define what alternative unit 1/alternative unit 2, and unit 1/unit 2 is used for. The idea behind these options is to give each customer more flexibility when using different units during the production.

Alternative unit2

recalc factor

Same as above.

Unit 1/2

This choice will correspond

to the choice made in recalc factor 1/2. For now, you can

select between "None", "Kilos", "Units", and "Meters". The

selected unit has to correspond to the selected unit the selected part is being produced in.

Full scrap qty an entire package

This is used when calculating % of scrap qty of an

entire package. For example, in the special function "5 Start order via part" or

the special function "341

Report scrap through packages"

which both have separate documentation.

Quantity per package

This is used to

enter an amount of quantity for a specific package. This is also used

together with special function 341 Report scrap through packages. Here is more information

on how that works.