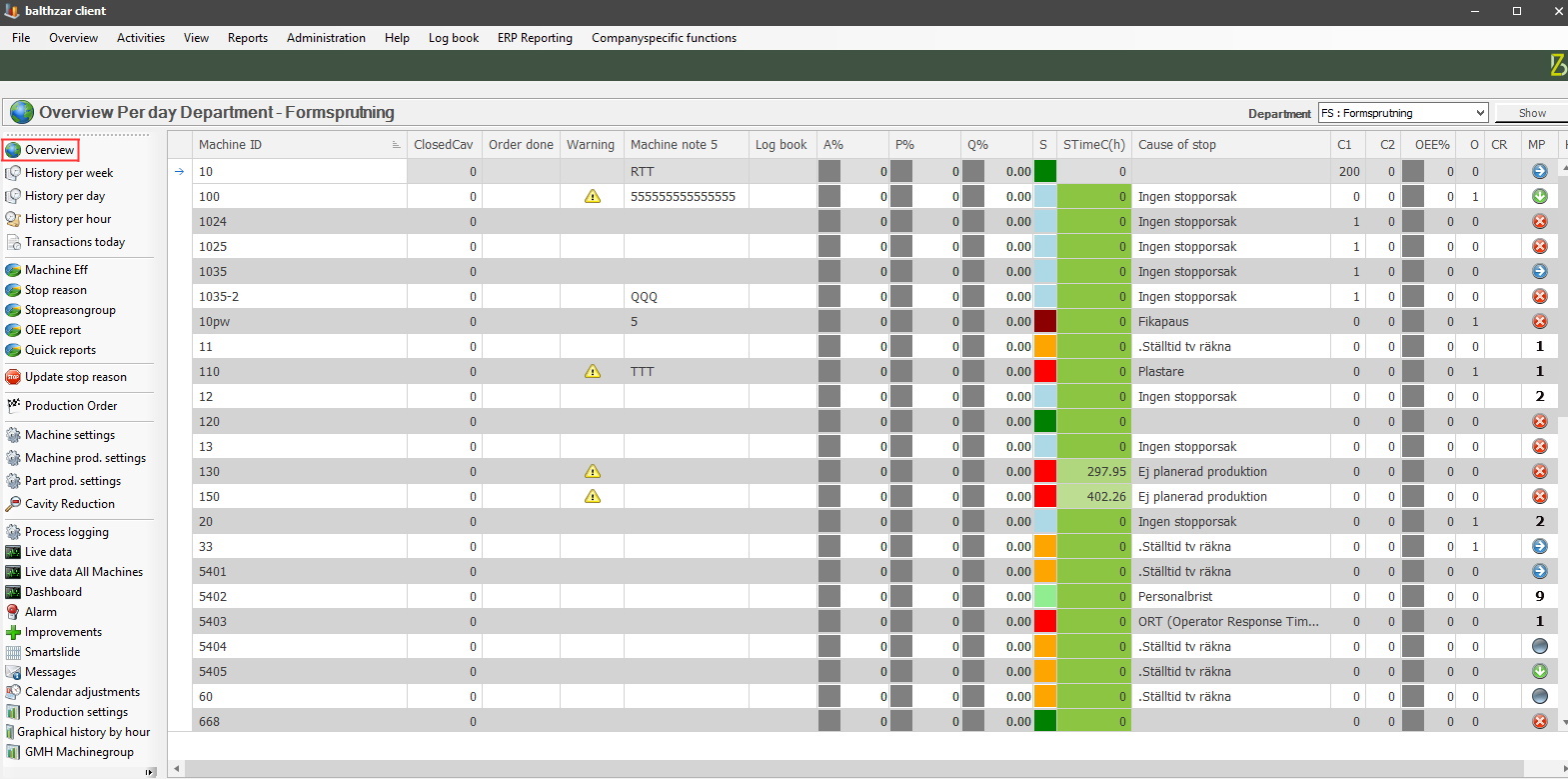

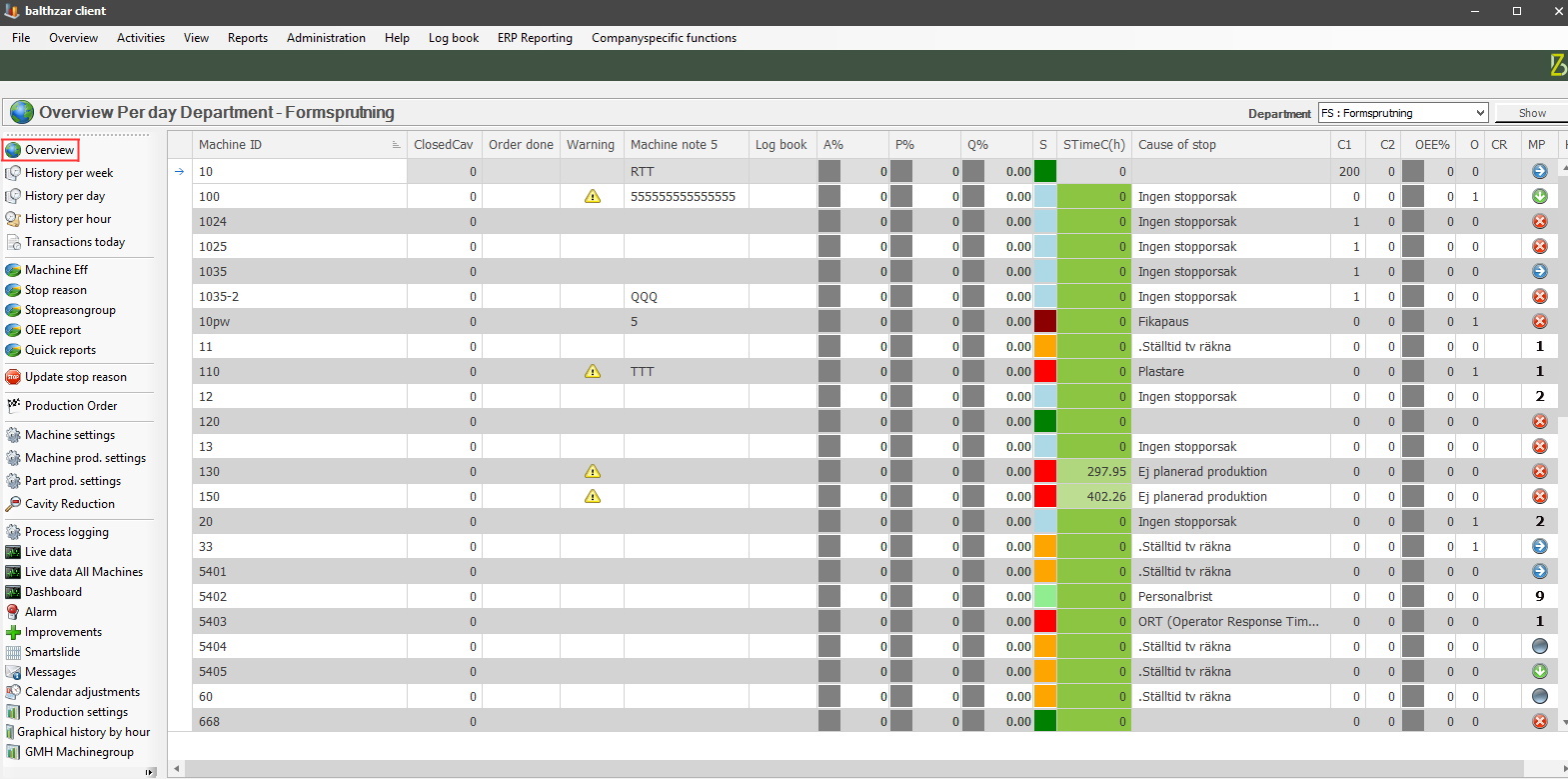

The idea behind the menu option "Overview" in Balthzar Clients left side menu is, as the name implies, to give the user an overview of available machines, their data, departments and so on. It also works as a short cut if you are on one of the sub menus, then just click on the "Overview" icon to return to it.

It is possible to change an Overview via "Client" -> "Main menu" -> "Overview" which has separate documentation.

The "Overview" in "Client" is customizable, and to activate it right-click on a column header, then choose "Column chooser". Once that is done a new menu will appear in the bottom right corner where more options will be available to further customize the "Overview".

It is also possible to add the special function "232 - 236 machine note 1-5" via "Client" -> "Administration" -> "System settings", "eTouch" -> "Special functions by machine". In that list select the machine/s that should have machine notes and activate it. Below there will be more information regarding what each column does.

Machine ID

Displays

Machine ID. This is entered in the field Machine ID in

"Client" -> "Administration" - "System settings" -> "Basic data"

-> "Machines" -> "Machine parameters 1".

ClosedCav

Displays closed cavities.

Order done

Data seen

here will show when the work order is intended to be finished. Only active work

orders can be visible here. If the machine is not active, and/or, does not produce anything, then this

column is empty.

Warning

In this column a yellow triangle

can appear. This symbol is a warning that indicates that the machine

does not receive any data. if this happens contact the system admin, or Delacroys support for

further help/assistance.

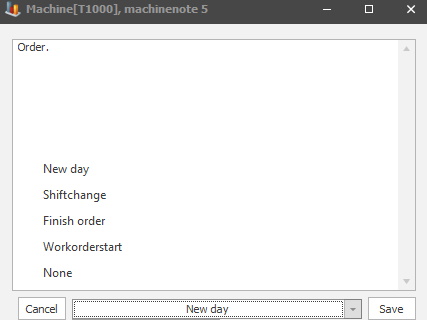

Machine

notes

From version

22.5.0 this is now standard functionality. Now

it is possible to use machine notes in the Overview in the Client without the

special functions 232-236. Here

is more information on how they work. In the notes users

can add extra information about the machine.

The drop-down menu can be used to reset whatever information entered here. For example, if a note is done about a specific order, then the options for work order start, or work order finish can be used to reset the note.

This will also be standard functionality in eTouch, and have its own menu in the eTouch main menu. Here is more information on how it works in eTouch.

Log book

Here you will be able to see more information

from the log book if such settings are done.

A% P% Q%

Depending on what settings the user has done

in tools -> options -> basic data -> users -> "Overview" ("Per day",

"Per shift", "Per 24h" or "Calendar") A%, P% and K% will display different

sets of data at the same time.

Each column has a square next to its value. This square will be red if the corresponding value = < entered Yellow limit in %, yellow if value > entered Yellow limit in % but < entered Green limit in % and finally green if value = > entered Green limit in %. Go to "Client" -> "Administration" -> "System settings" -> "Basic data" -> "Machines" -> "Machine parameters 1" to enter the information for this.

A%

Availability in precent

for selected part.

P%

Production in % for selected part.

Q%

Quality in % for selected part.

It is especially important to remember that when you calculate P%, it is done for the entire day, but its tool tip will display information that says it is only done for now active order. The consequence of this is that if you have completed two orders the same day and the first order has an extremely low value, it will have a negative impact on the P% total value. If the second order had an extreme high value, it will have a positive impact on the P% total value. If you move the mouse cursor to the square displaying P% you can see planned and actual speed. If for example the planned and actual speed would be 50/50 you could think that A% must be 100% however that is not the case because these numbers only show the current active orders status.

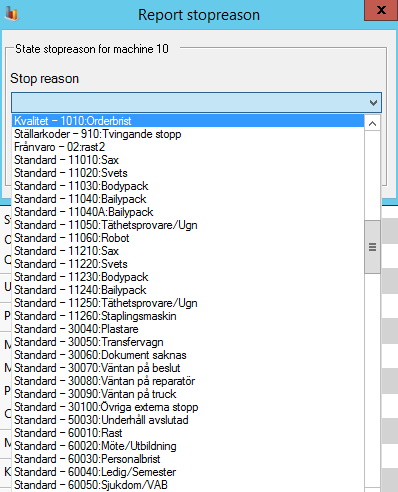

S (Status)

Status is

connected to a stop reason, and will be visualized through colors. This can

be created/edited via "Client" -> "Administration" -> "System settings"

-> "Basic data" -> "Stop reason" -> "Stop reason 1". Here is more

information on how this works. To change a stop reason in the Overview, click

on the color icon, and you will see a list

of available stop reasons.

STimeC(h) (Stop time in hours)

Time in

hours for current stop reason.

Cause of stop

Here you will see a description of the current

stop reason.

C1/C2

Number of cycles entered in counter 1 or

2.

EE%

Here you can see a summary for Equipment

Efficiency % (EE%).

O

Number of orders currently active.

CR

Number of cavity reductions. < /FONT

>

< /SPAN > < /P

>

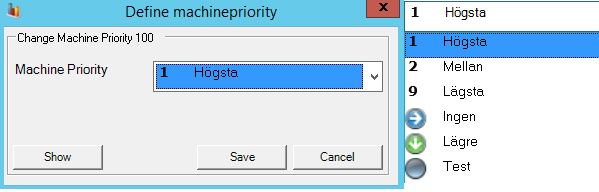

MP

Here you can see what current priority level each

machine has, as well as change it. This should be done by system admin.

Right-click in the column for MP in the Overview in the Client to see the

menu below. To activate this column, go to "Client" -> "Administration" ->

"System settings" -> "Basic data" -> "Users" -> "Machine

priority". Here

is more information on how this

works.