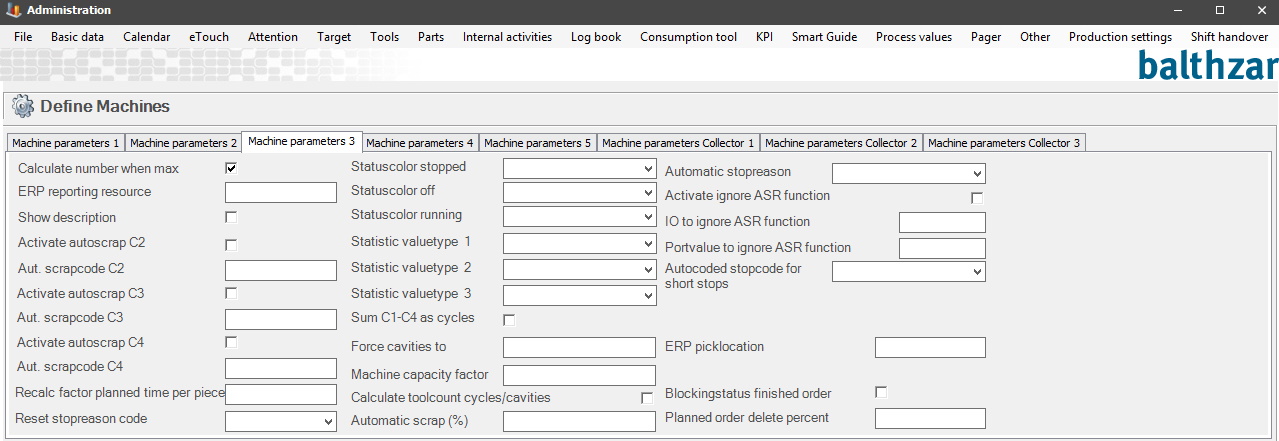

Here are the settings for "Machine parameters 3".

Calculate number

when max

If this setting is applied, the

system will assume that the databox will count to its defined max-value and start

over at 0.

ERP reporting resource

States which resource name

this machine should use when reporting back to the ERP system. If this field is

left empty, the system will use the ERP Resource from machine parameters

1. Here

is more information about how that form works. If both fields are left empty, then the connection to the ERP

system will not work as intended.

Show description

Displays

machine description instead of machine ID

in various places of the system.

Activate auto scrap C2/C3/C4

If this setting is active then all

quantities registered on counter 2/3/4 in the system will be scrapped with the

note "Aut scrap code C2/C3/C4".

Aut.scrapcode C2/C3/C4

Scrapcode used when auto scrap occurs on counter

2/3/4.

Recalc factor planned time per piece

The factor used when recalculating planned cycle time.

Normally this should be set to 1 = No recalculation.

Used when the planned time supplied by the ERP system needs

to be recalculated in some way.

Reset stop reason code

Stop reason code to be sent to the server when stop reason should

be reset. This could be a stop reason or just a code resetting the

stop reason.

Status color stopped

Customer adaptation, used by company ID 5066 in their

Attention-slides.

Status color off

Customer

adaptation,

used by company ID 5066 in their

Attention-slides.

Status color running

Customer adaptation, used by company ID 5066 in their

Attention-slides.

Statistic value type 1/2/3

Customer adaptation, used by company ID 5066 in their

Attention-slides.

Sum C1-C4 as cycles

When checked, the system will add all counters

from the first four counters and treat this sum as cycles.

Force cavities

to

Forces

the use of a certain number of cavities

regardless of what is entered at the tool used. The supplied value will be

set on all started orders regardless of other settings.

Machine capacity

factor

Forces the use of a certain capacity

factor at a machine. Overrides all other logic related to this value.

Normally, this value comes from the planned order. The value should be

entered in the format

0.85 indicating an 85% capacity

factor. This value is used when estimating when an order should be

finished.

Calculate tool count cycles/cavities

Adds to the counters on tools used, defined in

Balthzar.

Automatic scrap

%

Here you

can enter a number that will determine how much of the produced

quantity should be automatically scrapped. The number entered here will be

interpreted as %, so if you enter the number 5 that means 5% will be

automatically scrapped. The quantity will be scrapped with the assigned scrap

reason from scrap code scrap

management

in

machine parameters tab 2. Every 20 minutes there will be a scrap created

per order in that interval.

Automatic stop reason

In this drop-down list the selected stop reason

will get the stauts "Automatic stopreason". This will be active

until the machine stops. Stop reasons are created in the admin-section

for Stop reasons which have separate documentation via "Client" ->

"Administration" -> "System settings" -> "Basic data" -> "Stop reasons"

-> "Stop reason tab

1".

To set a specific time for the duration of the selected

stop reason go to "Client" -> "Administration" -> "System settings" ->

"Basic data" -> "Stop reason tab 2" -> "Max time before reset

at automatic stop reason".

Activate ignore ASR function

Function to activate if ignoring the ASR function

should be applied.

Port value to ignore ASR function

If this port receives a "1" value, the "Activate

ignore ASR" function gets activated, and a "0", is

de-activated.

ERP picking location

Deprecated function.

Blocking status finished order

If this checkbox is activated, a warning will appear when

the production of a work order has reached the planned quantity for that work

order. It is also possible to change the appearance of the warning. Read more

about it in the documentation for special function 30 Warning work order

done.

Planned order for delete percent

Here it is possible to enter

a numerical value, and that value will act as a threshold value for

the system which will hide the work order when this percentage of the

planned quantity is reached. it is still possible to run the work order, and the total

number of good quantity can exceed the planned

number of good quantity. However, when the work order is finished it will disappear from the planning. The

same applies if the work order is only produced

to the entered percentage specified here.

OBS! Be aware that this functionality was designed to not use a value higher then 90. If a higher value is needed, this function should be used at all. To make sure this function is not used, enter the number 0 (zero) in the column for "Planned order for delete procent".

Depending on how work orders are imported to Balthzar, the work order can be removed by another ERP system during the next synching. If the work order was registred manually in Balthzar, then it is not removed at all. However, it will not be visible since the remaining quantity is less then, or equal to 0 (zero).