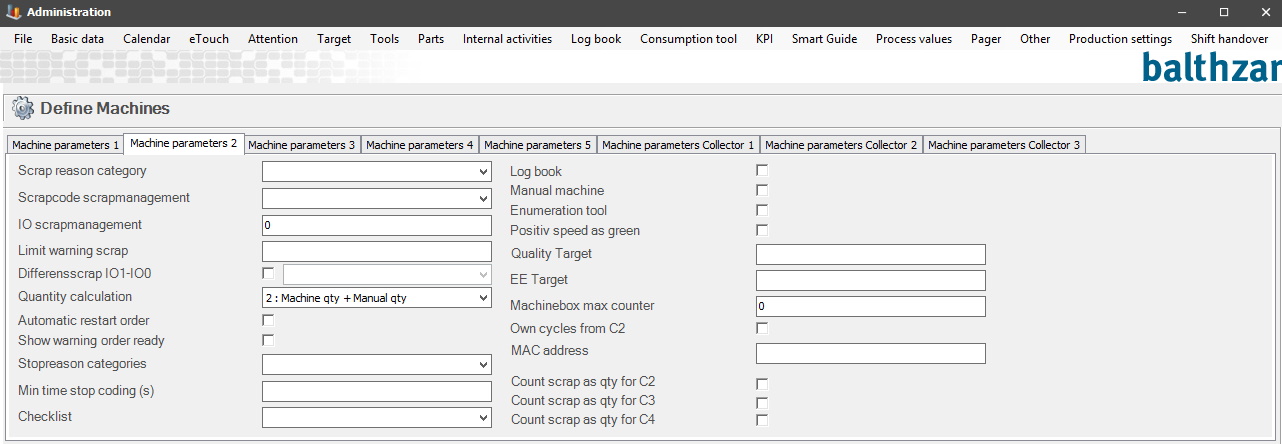

Here are the settings for "Machine parameters 2".

Scrap reason

category

This determines which scrap reasons are visible in

eTouch. If no group is selected, all scrap reasons are visible.

To edit old categories/create new ones go to "Client" ->

"Administration" -> "System settings" -> "eTouch" -> "Scrap reason

category". Here

is more information on how this works.

Scrap code scrap management

In this drop-down menu it is

possible to select a scrap code that will be used as a basis for scrap

management on the active machine. If this is not supposed to be used, then

select "None" in the list. When this is activated the system will count

everything produced with this scrap reason as scrap.Used in conjunction

with IO scrap management.

It is also used in conjunction with "Automatic scrap

%"

which can be found in the tab for machine parameters 3.

IO scrap

management

Used in conjunction with the parameter

above, "Scrap code scrap management". Here the IO-port of the databox

is entered which tells the system that scrap management is in effect, by

sending a constant high signal (1).

Limit warning scrap

In this

field you enter a numerical value, and that value will represent a limit for

when the system should give a warning for excessive scrap value. For example, if

2,5 is entered here, then the system will provide a warning if the scrap is

higher than 2,5%.

The

calculation is made of the current work order for the current day.

Differentialscrap IO1-IO0

When this function is activated a check is

made every 15 minutes examining the difference between cycles and counter 2. This

difference, if any, will result in scrap coded as "Scrap code

management".

Quantity calculation

The options here will determine how Balthzar will register

quantity in the system. Either, the reporting will be done manually by

the machine, the first option. Or quantity will be reported manually

by the operator, the third option. However, the most common is the

second option, which is a combination of option 1 + option 3.

1. Only machine quantity.

2. Machine + man. quantity.

3. Only manual quantity.

Choice of how quantity should be calculated. Most

commonplace is alternative 2, which adds machine quantity and manual

quantity. Keep in mind that time per piece is always based on machine quantity, except

in the case of manual machines. When manual machines are used, time per piece is

calculated from manually reported quantities.

Automatic restart order

Customer adaptation.

Show warning order

ready

If this check box is activated,

then a warning will be visible in the Overview in the Client. To

determine when this warning should go active, go to "Client" ->

"Administration" -> "System settings" -> "Basic data" -> "Users" ->

"Remaining time (min)". Here is

more information on how that form works.

Please be aware that there are two identical checkboxes for "Manual machine". This one here, and the other is in the eTouch parameters 2 form. The difference between them is where in the system the status of the machine is changed to manual machine. This one will change the status to manual machine for the Client, the other for eTouch.

OBS! If the web application BZX21 is used, then BOTH of the checkboxes must be activated in order to change the status of the machine.

There is a Widget called Manual machine. This Widget MUST have both checkboxes for manual machine activated to work as intended. To add Widgets in BZX21 go to the top right corner of the interface. In that menu go to the option called "Edit Template". This is where Widgets are added / removed in BZX21.

Enumeration tool

States whether enumeration is used on this machine. If it is

not activated, cycles will not be added to the consumption tool used, even if it

is configured to do so in the order.

Positive speed as

green

States that speed above 100 should be

shown as green. (Obviously, the faster details are produced, the better. However,

if details are produced faster than a certain speed, quality might suffer, and

therefore might be considered something that needs to be adjusted.)

Quality target

This

setting is connected to special function 114 which is a customer

specific solution.

EE target

This setting is connected to special function 114 which is a customer

specific

solution.

Machine box max counter

States the highest value the databox can have

before starting over at 0. Should be set to 0 in databoxes from Advantech,

varies on others. Please consult your supplier before this parameter is

configured.

Only used if calculate quantity at max value

is set.

Own cycles from C2

This is

used if the machine box sends more than one signal to the system. If that is the

case this checkbox can be activated and it will calculate own cycles from

the second signal and Balthzar status will calculate the Own quantity

(machines own_cycles_today) using C2.

MAC address

Here you enter a

MAC address for the machine, usually done by the system administrator.

Count scrap

as qty for C2/C3/C4

If the machine box used sends more than one

signal to the system, then it possible to use any/all of these checkboxes. The

system will then count scrap as quantity for C2/C3/C4. It is calculated by Balthzar Status, (my_cycles_today),

based on the corresponding signal from the machine

box.