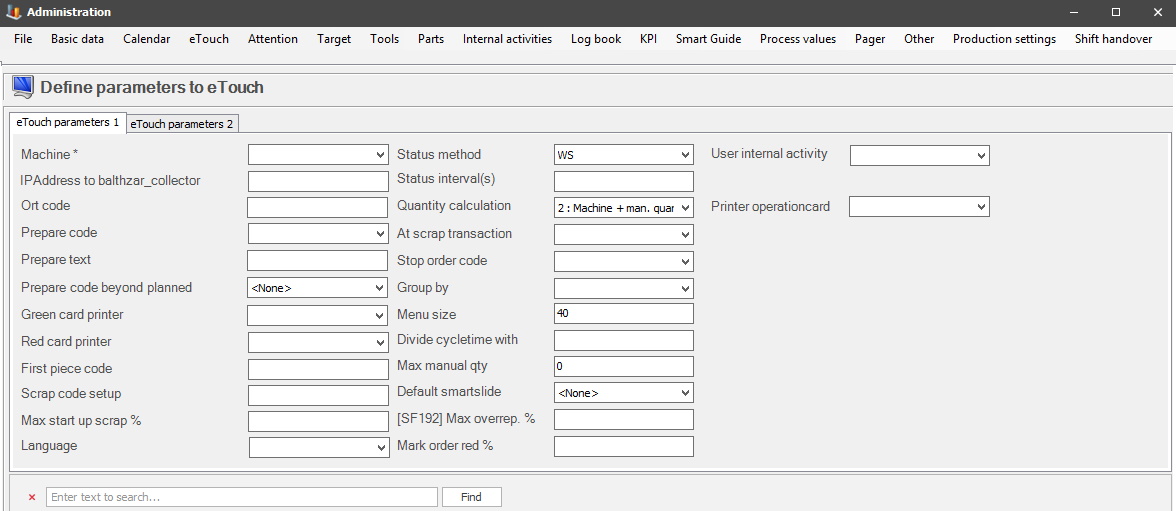

OBS! The settings for eTouch parameters 1 / 2 will also affect the web application BZX21.

Here you will find the settings for eTouch parameters tab 1. From version 24.6.0 and onwards the search bar is activated as standard.

Machine

Here you select the

active machine. To set up a new machine, and/or edit an old machine, go to

"Client" -> "Administration" -> "System settings" -> "Basic data"

-> "Machines" that section

has separate documentation.

IP Address to Balthzar

collector

The IP address to be used when eTouch needs

to communicate with the Balthzar collector, which is the case when printing occurs.

ORT Code

The code to be sent to

the system when the operator has acknowledged a stop but has not yet set the

stop reason.

Prepare code

This code is

sent to the system before an order is started, indicating that calibrating

of the machine is in progress. These codes can be added via "Client" ->

"Administration" -> "System settings" -> "Basic data" -> "Stop reasons"

that section has separate documentation.

Prepare text

This text is sent

to the system before an order is started, indicating that calibration of the

machine is in progress.

Prepare code beyond

planned

Here you can select a stop reason that will be in effect if

the machine has exceeded the started orders planned set-up time.

Green/Red card printer

Here you

can select what printer should be used when printing green or red cards from

eTouch.

First piece code

This code is

sent to the system as soon as the first approved prime quantity piece is

produced after calibration. This code is part of the calibration of the machine

before starting the actual manufacturing run.

Scrap code setup

The scrap code

is used to indicate that setup is done. Used separately to make follow-ups

easier.

Max start-up scrap %

Prevents

that more than a certain percentage is registered as scrap (of total

planned quantity) during setup. Primarily used to prevent typos like "1000"

when it was meant to be "100" instead.

Language

The language used in

eTouch.

Status

method

The method

used when fetching the status of the machine. You can choose WS = Webservice or

TCP = Network. OBS! TCP is no longer supported. Contact our support

if any additional information/help is needed.

Status interval(s)

The number

of seconds eTouch should wait before ordering, a status update for the machine

specific values in, the eTouch production order menu. Specifically, the values in

the top section of the menu including, Reported stop reason to OEE Today. Here

is more

information on these values.

Keep in mind that a status update of the system is quite an expansive operation in terms of server resources and should be configured with this in mind. Generally speaking, a setup with 10 or fewer machines can have a relatively short interval such as 10 seconds.

However, more than 10 machines will need more time, and you also have to take into consideration how old the hardware of the computer is since this will also affect the time needed to perform a status update.

Please note that the minimum value that can be entered here is three, 3. If a number lower than three, 3, is entered, then the system will still count it as a three,3.

Any changes here should be made by the system administrator. Contact Delacroys support if any additional help/info is needed.

Quantity calculation

States

how quantity is calculated, i.e., if quantities should be reported by

databox, manually or manually, and from a databox.

At scrap transaction

Setting which states how the system should calculate scrap

quantity, either by reducing the prime quantity or as a scrap report separated

from prime quantity. The difference here is how it will be reported. Either

by first reporting produced quantity, and then scrapped

quantity, or produced prime quantity, and then

scrapped quantity.

Stop order

code

Code

is sent to the system automatically when an order is stopped. This is not

the same as an order being finished. This is user defined and set

up together with the developers at Delacroy. Stop codes has separate

documentation.

Group

by

States which other

machines are shown in the eTouch overview, i.e., those in the same group as the

current one. Here

is more information on how "Department/Zone/Category" works.

Menu size

Defines the size of the menu items in eTouch. Size 40 is the

default.

Divide cycle time

with

A factor in which cycle time should be divided within eTouch,

to compensate for irregularities for this machine.

Max manual

quantity

The maximum manual quantity allowed to be reported. This is

used to avoid manual typing errors such as "1000" when "100" was intended.

Default smart

slide

The

smart slide is shown as a startup screen in eTouch if the special function

"96 Info page as start page" is used, here you can read more about how

that special function

works.

[SF192] Max. overrep. %

The maximum quantity allowed to be reported

on the order in correlation to the planned quantity. The idea here is

to prevent typos like "1000" when "100" was intended. OBS! The special function

192 HAVE to be activated for this to work. Here

is more information on how

this special function works.

Mark order red

%

If a number is entered here, it will represent the

amount of good quantity, in percent (%), the system needs to produce before the

work order in progress will be marked with a red background. This is intended to act as

a warning signal to notify the operator that the current work order will

be finished soon. It is possible to leave this empty, but then

the system will use the standard value of 90 automatically.

User Internal

activity

Here you can choose a specific user in a

drop-down menu that will have access to Internal activities. Internal

activities have separate documentation

that will explain how it

works.

Printer operation

card

Here you can choose which printer should print operation

cards.